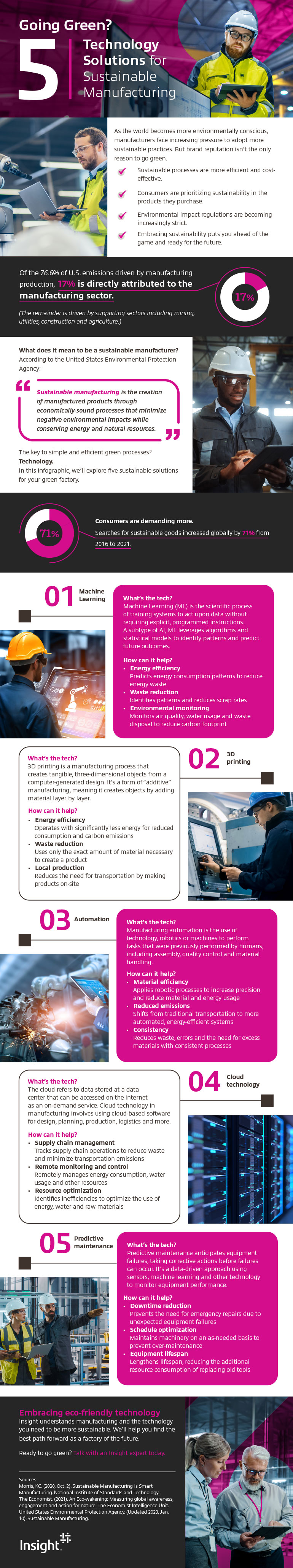

As the world becomes more environmentally conscious, manufacturers face increasing pressure to adopt more sustainable practices. But brand reputation isn’t the only reason to go green.

- Sustainable processes are more efficient and cost-effective.

- Consumers are prioritizing sustainability in the products they purchase.

- Environmental impact regulations are becoming increasingly strict.

- Embracing sustainability puts you ahead of the game and ready for the future.

Of the 76.6% of U.S. emissions driven by manufacturing production, 17% is directly attributed to the manufacturing sector.

(The remainder is driven by supporting sectors including mining, utilities, construction and agriculture.)

What does it mean to be a sustainable manufacturer?

According to the United States Environmental Protection Agency:

“Sustainable manufacturing is the creation of manufactured products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.”

The key to simple and efficient green processes? Technology.

In this infographic, we’ll explore five sustainable solutions for your green factory.

1.Machine learning

What’s the tech?

Machine Learning (ML) is the scientific process of training systems to act upon data without requiring explicit, programmed instructions. A subtype of AI, ML leverages algorithms and statistical models to identify patterns and predict future outcomes.

How can it help?

- Energy efficiency

Predicts energy consumption patterns to reduce energy waste - Waste reduction

Identifies patterns and reduces scrap rates - Environmental monitoring

Monitors air quality, water usage and waste disposal to reduce carbon footprint

2.3D printing

What’s the tech?

3D printing is a manufacturing process that creates tangible, three-dimensional objects from a computer-generated design. It’s a form of “additive” manufacturing, meaning it creates objects by adding material layer by layer.

How can it help?

- Energy efficiency

Operates with significantly less energy for reduced consumption and carbon emissions - Waste reduction

Uses only the exact amount of material necessary to create a product - Local production

Reduces the need for transportation by producing products on-site

3.Automation

What’s the tech?

Manufacturing automation is the use of technology, robotics or machines to perform tasks that were previously performed by humans, including assembly, quality control and material handling.

How can it help?

- Material efficiency

Applies robotic processes to increase precision and reduce material and energy usage - Reduced emissions

Shifts from traditional transportation to more automated, energy-efficient systems - Consistency

Reduces waste, errors and the need for excess materials with consistent processes

4.Cloud technology

What’s the tech?

The cloud refers to data stored at a data center that can be accessed on the internet as an on-demand service. Cloud technology in manufacturing involves using cloud-based software for design, planning, production, logistics and more.

How can it help?

- Supply chain management

Tracks supply chain operations to reduce waste and minimize transportation emissions - Remote monitoring and control

Remotely manages energy consumption, water usage and other resources - Resource optimization

Identifies inefficiencies to optimize the use of energy, water and raw materials

5.Predictive maintenance

What’s the tech?

Predictive maintenance anticipates equipment failures, taking corrective actions before failures can occur. It’s a data-driven approach using sensors, machine learning and other technology to monitor equipment performance.

How can it help?

- Downtime reduction

Prevents the need for emergency repairs due to unexpected equipment failures - Schedule optimization

Maintains machinery on an as-needed basis to prevent over-maintenance - Equipment lifespan

Lengthens lifespan, reducing the additional resource consumption of replacing old tools

Embracing eco-friendly technology

Insight understands manufacturing and the technology you need to be more sustainable. We’ll help you find the best path forward as a factory of the future.

Ready to go green? Talk with an Insight expert today.